Building the Main Staging Yard, part 2

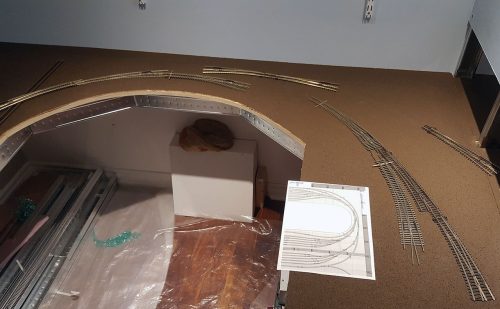

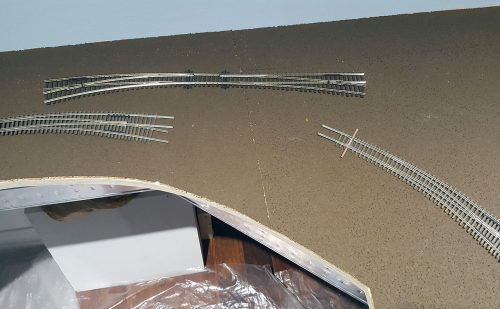

Work continues in the staging with the MoW crew busy test-fitting the West ladder of the main yard. Turnouts are so much more fun as things can always go wrong. Straight track is just that – straight, but for turnouts you need to drill holes for the motor, feeders, etc.

Finally turning the corner so we’ll see how good those custom curved turnouts really are. So far they feel pretty brittle, and I’m not a big fan of using CA glue to connect rail to the turnout tie template – too big of a twist and the rail pops out.

I think I will go back and replace some of those plastic ties with PCB ties. I did not want to start with PCB ties because it would’ve made it harder for me to fit all into the template that would’ve been cut in multiple pieces.

Looking at some of the placement here, I’m not quite sure whether this will work out as planned. Because I use AnyRail for layout design, it does not have a Central Valley Turnout templates, and I had to use FastTracks ones instead.

Turns out the turnout geometry is not exactly the same with angles being slightly steeper on FastTracks and everything fits nicely…in the digital world. Transferring to the real world and CVT being just a notch larger radii things become out of wack and I run out of space. Blasted room being only 12 ft. wide!